From sheep barn to $1.4B global innovator: How Iowa’s Kemin Industries built a multigenerational science business

Gigi Wood Sep 26, 2025 | 6:00 am

16 min read time

3,910 wordsAll Latest News, Business Record Insider, ManufacturingMolecules are the building blocks of life and are the foundation of a multigenerational Iowa manufacturing business.

Des Moines-based Kemin Industries is a $1.4 billion ingredient supplier run by the founding family’s second generation, who have gamed out a detailed succession plan. Globally, the company employs 4,000 people, with 800 of those in Central Iowa and 650 on site at its headquarters. At least six of those employees are part of the founding family.

Simply put, Kemin makes science-based ingredients designed to keep crops, animal feed, pet food and clothing safer, healthier and longer-lasting.

The company has leveraged its technological innovations in molecules and enzymes to create animal feed additives, ingredients for human, pet and livestock food, and vaccines, as well as crop protection, textile and biofuels solutions.

Kemin’s business units include:

- Animal nutrition, health and vaccines: Products designed to keep livestock fed and disease free.

- Aquaculture: Farmed fish feed stabilization and ingredient solutions for pond, disease and food management.

- Biofuels and bio-solutions: Ethanol yield solutions with enzymes for ethanol production and antioxidants for biodiesel.

- Crop technologies: To improve plant health, Kemin provides pest control and plant health nutrition supplements.

- Food technologies: Plant-based extracts, antioxidants and antimicrobials to improve food safety and shelf life.

- Hemp: Hemp products derived from Cannabis sativa L. for select markets.

- Human nutrition and health: Natural ingredients to support vision, cognition, immune health and weight management.

- Pet food and rendering technologies: Products and services that keep pet foods safe and palatable.

- Textile auxiliaries: Chemicals for clothing and textiles. Kemin enzymes are used for bio-stoning or natural stone washing jeans, without the need for pumice stones.

Kemin’s roots

R.W. Nelson grew up in Des Moines, where he graduated from Dowling High School. Next, he spent a year at Drake University before serving three years for the U.S. Air Force as a crew chief on B-29s in the Philippines during World War II.

When he returned, he continued his studies at Drake, graduating in 1950 and then worked as a salesman and district supervisor for McKesson & Robbins, an animal feed additives and pharmaceutical distributor and then worked at Flavor Corporation of America.

During the early 1960s, mold in animal feed had caused the death of 100,000 turkeys in the United Kingdom. Nelson developed an idea for a mold inhibitor to be used as an additive in livestock feed, but his employers didn’t take him up on it. Nelson ventured out on his own, and in 1961, he. and his wife, Mary, started the company that is now Kemin Industries.

R.W. Nelson used a wool barn owned by his father to produce products like a sheep dewormer in a Maytag wringer washer, feed flavors, mold inhibitors, hay and silage preservatives and applicators for hay and silage treatments. Mary ran the office out of the family home while raising their five children.

That same decade, the company began exporting, a move that was not commonplace at the time in Des Moines.

“My parents called on my aunt who had exported concrete from Newton, and then called on bankers in Cedar Rapids to get a letter of credit, because Cedar Rapids did have companies that exported, like Rockwell Collins and Quaker Oats and they figured it out,” said Libby Nelson, Kemin’s vice president and general counsel. “Once they had done that, I think that’s when R.W. and Mary recognized that there’s this whole wide world out there with customers with the same pain points as U.S. customers that could use Kemin products.”

Kemin now operates manufacturing facilities in Europe, North and South America, Africa, India, Singapore, China and Russia, to be closer to customers in 120 countries.

Commitment to global and regional markets is an important part of exporting, she added.

“Our customers told us in Europe and in Asia, ‘If you want us to buy stuff here, you need to commit, you need to come and be with us,’” she said.

Second generation

The five Nelson children spent their Saturdays at their grandfather’s Bart Nelson’s sheep barn, herding sheep from pen to pen and catching wool bundles at shearing time while their dad worked. Their grandfather would often grill hot dogs for lunch and give them a dime for the pop machine. When they grew a bit older, they would work from home, where they set up a small assembly line to put together applicators for Kemin.

They were encouraged to attend college, explore the world and work for different employers before returning to Des Moines to join the family company, if they were interested in working at Kemin and if a position was open.

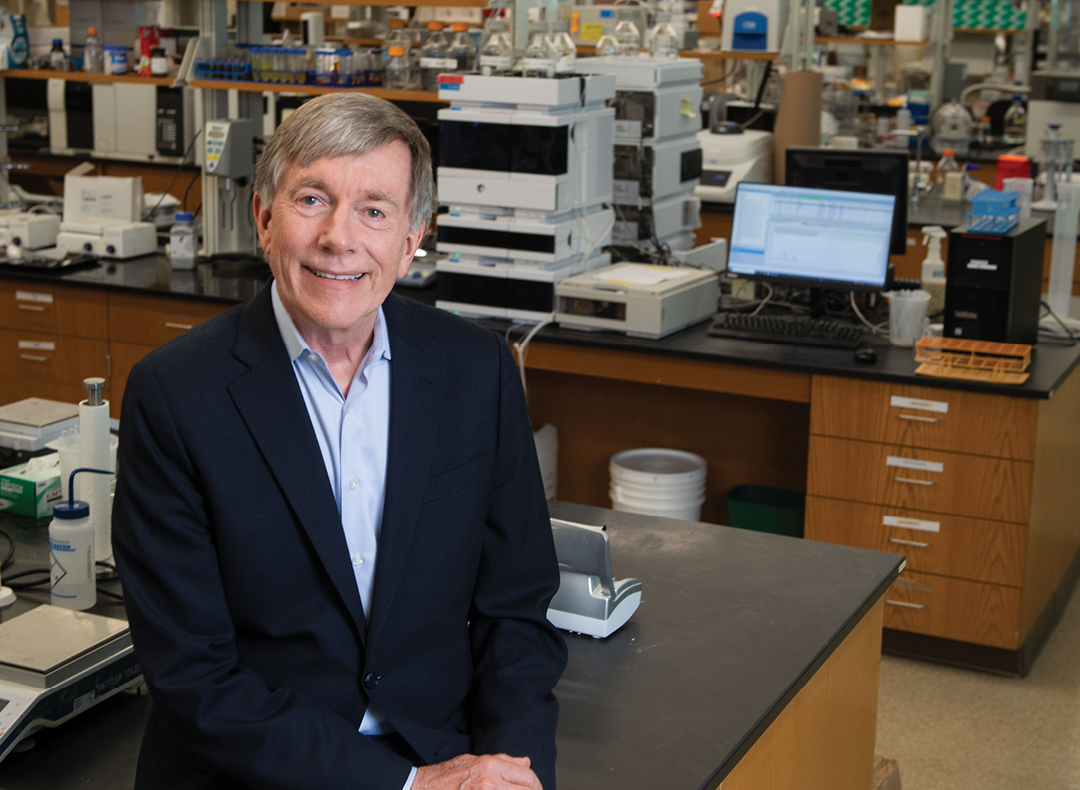

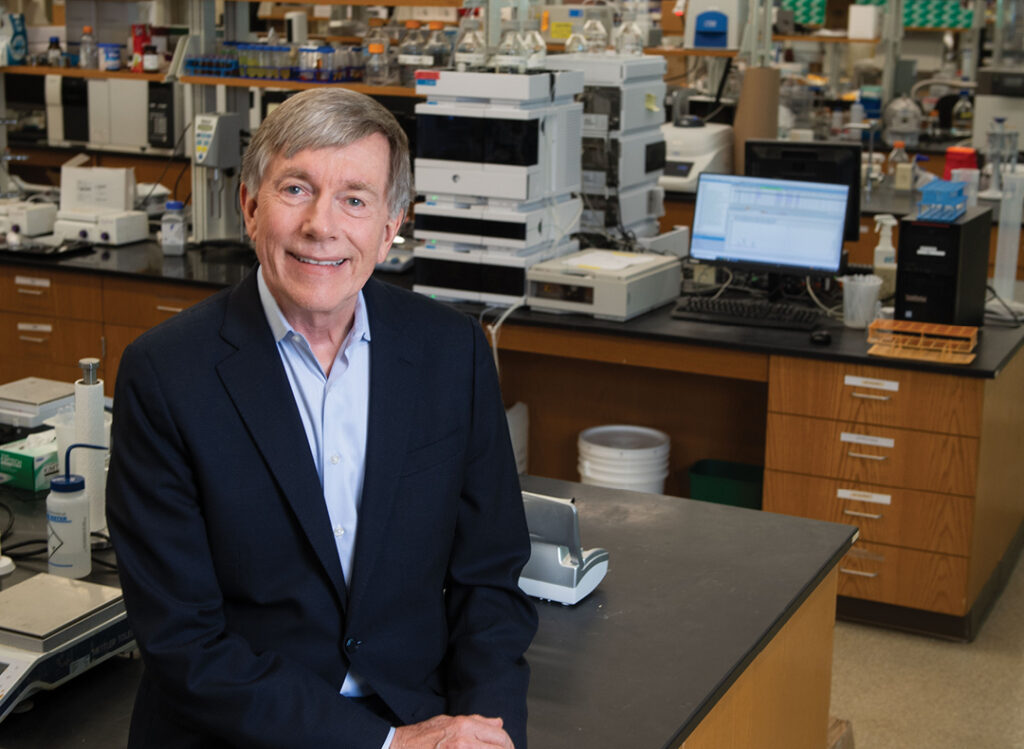

Eldest son Chris Nelson studied science at Northwestern University before attending Washington State University, earning a doctorate in biochemistry and biophysics. He and his wife spent three years in Herentals, Belgium, where Kemin operated a regional headquarters that needed a research director. He returned to work at the Des Moines location in 1983. His daughter, Kimberly Nelson, has joined the company.

Libby Nelson, the second oldest child , attended Washington University in St. Louis before earning her law degree from Drake University. She started out working for a trust company in Milwaukee before returning to Iowa in 1981. She served the state of Iowa in the Department of Aging and the Attorney General’s office and worked in private practice before joining Kemin, where she is now vice president and general counsel.

R.W. and Mary Nelson’s other children – Janet, David and Molly – are less involved with the day-to-day operations of Kemin. Janet Nelson worked for Kemin for many years before starting her own venture, David Nelson has served on Kemin’s board of advisors and consults on real estate transactions. Molly Nelson Ryan serves on the company’s board of advisors and many other family members sit in on the larger company meetings.

A new era of product development

When Chris Nelson returned to the United States in 1983, he wanted to better understand why Kemin products worked the way they did. Understanding this would build stronger relationships with customers and could lead to new discoveries, he said.

He pivoted from the laboratory to the head office in 1999, when he was named president of Kemin North America. His father, who passed away earlier this year, stepped into the chairman role at that time; he stayed active in business managing and sales training until the last two years of his life, the family said.

Until about 1980, Kemin focused on the animal feed business. Then they started asking more about the “why” and “how” of their products, and a new era of product development began. They realized the enzyme cellulase could be used in applications other than animal feed. They researched products originally used to pigment chickens and eggs and recognized that the carotenoid lutein could also be used to support human eye health. Also, antioxidants formulated to stabilize fat in animal feed proved suitable for pet food, and enzymes developed for animal feed and baking found applications in textile manufacturing. Through these discoveries, Kemin created new growth across multiple markets and industries.

“If you look at all of our different businesses, we’re in textiles, we’re in animal feed, we’re in human food,” Chris Nelson said. “What is common to all of those businesses is they share the same molecules.”

Cellulase, which improves the digestibility of animal feed, can be used to apply a stone-washed look to denim jeans.

“The streaking used to be caused by stone washing. There was a discovery that the same cellulase that we’re using in animal feeds could be added instead to a giant washing machine, where they have like, 500 pairs of jeans in it. When you add [cellulase] to a washing machine you don’t need to have the stones, which have all sorts of ecological problems,” he said. “Add the enzyme to the equipment and it gives you the same effect. Our approach was, ‘OK, we don’t know much about the textile industry. We know about this chemistry, and we know the molecule.’ We said ‘OK, we’ll get into this industry and learn the markets.’ That has been the concept — to truly understand the molecule, how it works, and then apply it to various industries.”

Succession planning

R.W. and Mary Nelson began talking about family succession in the early days of the business and about 20 years ago, the Nelson family decided to keep the company in the family for a minimum of seven generations.

“Why seven? Well, that turns out to be approximately when Kemin would be 200 years old. So it’s really a 200-year vision,” Chris Nelson said.

The family has compiled family succession practices from around the world to help shape their future plans.

“In Europe, it’s not unusual to find family businesses that have been in business for 16, 20 generations,” he said. “To be able to get to seven generations, there’s obviously some best practices, and we’ve been religiously trying to follow those.”

The Nelsons have developed a family constitution, a set of rules and processes that they follow to guide succession, which they all sign in agreement. For example, when a Nelson gets engaged to a future spouse, that fiance comes to Des Moines for a two-day training class to learn about the business and the rules of the succession plan.

“I always ask at the end to the spouse-to-be, ‘Are you sure you still want to get married?’ And so far, everybody has said ‘Yes,’” Chris Nelson said.

Chris Nelson and his sister Libby Nelson are the two active family members from the second generation of the family business. There are four family members from the third generation active in the business, and they are working on introducing the family business to the fourth generation, the oldest of which is 8 years old.

“We’ve got eight members of G4 and we outfitted them with coloring books that we created just for that group,” Chris Nelson said. “It’s a Kemin coloring book, so they start to learn about the business. At the annual shareholder meeting in July, we outfitted all of them in laboratory coats and took them on a tour to show them some of the things we do in the lab.”

Chris Nelson shared four insights for running an effective succession plan:

- The family has to be united on the vision for the business.

- Family members need to be actively working in the business.

- Transparency about how the business is performing and how it operates is necessary.

- The rules and processes of how the succession will work are needed.

Libby Nelson also recommends families seek out solid financial, accounting and legal expertise while planning the future of the business and when looking at estate planning.

“We had some really talented people help us along the way,” she said.

Third generation

Kimberly Nelson, Chris Nelson’s daughter, attended Dowling and Northwestern like her dad, but never intended on joining the family company.

When she was young, she traveled with her dad to Singapore and enjoyed the cultural experience. While growing up in Des Moines, she took Chinese language lessons and after college, she pursued a marketing position for a fashion supply chain company in Hong Kong.

“I always thought I wanted to work in fashion, and for me, looking at Kemin, a chemical company, and looking at fashion, it seemed like two totally different worlds,” she said.

That changed when she was pursuing her master’s degree in luxury and fashion management from Savannah College of Fashion and Design. During her thesis project, she worked with a German chemical company that had invented a new fiber, and didn’t know what to do with it.

“I worked on the business plan for that, and during that time, my dad, who’s very familiar with this very large German company, is like, ‘Wait, what are you doing? I thought you were in fashion school.’ He started to understand there is this world of chemistry within textiles, and so that’s how we both opened our eyes that this was a much larger business than we ever saw. In fact, one of the main ingredients is a basic enzyme for animal feed that we’ve been working on for decades.”

She is now president of Kemin Nutrisurance, the company’s pet food and rendering technologies business unit. Before taking that position, she helped launch Kemin into the textile industry as president of Kemin Textile Auxiliaries.

“It was a great marriage of my passion and where the family business lies,” she said of her textile work. “I was very fortunate that I was able to find that path.”

The company vision and her grandparents’ and parents’ passion for the business drew her to Kemin, as well.

“[The company vision] is really something that I hope, and I think that a lot of our teams around the world feel extremely connected to,” she said. “That’s a big part of what our vision is also, because we are such a global company, we want to make sure that our scientists in India, who are super creative, feel the same as our logistics people in Brazil. They’re a world apart, they’re culturally different, but we want to tie them all together, and to do that, I think the vision is what gets us there.”

Kemin Nutrisurance manufactures products using natural and synthetic raw materials and chemical processes to produce ingredients designed to keep pet food from spoiling and safe from bacteria like salmonella and add flavoring. Kemin’s Nutrisurance products can be found in a large market share of the preservation chemicals used in pet food.

“It’s very likely a brand that you are buying at Petco, Target, Hy-Vee or Walmart has our freshness chemicals in it,” she said.

While some people might not like the idea of chemicals in pet food, she is quick to say they are the “good kind of chemicals.”

“There’s really not anything scary in pet food or human food anymore, it’s so highly regulated,” she said. “I think there’s a misconception that if the word is a big, scary scientific word, it means it’s bad. The first time I heard the word ‘tocopherol,’ I was like, ‘What is that?’ Well, it’s from soybeans and it’s incredibly natural and safe, and it’s great for making sure pet food doesn’t go rancid.”

Lucas Nelson, son of second-generation family member David Nelson, is group president of Bud & Mary’s, the cannabis offshoot of Kemin. Named after the founders of Kemin R.W., who was also called “Bud,” and Mary Nelson, the company develops and sells medical cannabis products for patients across Iowa, and similar products in other states, as laws allow. The cannabis industry was a natural fit for Kemin, where 42% of its products are derived from plants. Kemin doesn’t have an ownership interest in Bud & Mary’s, but does provide technical support to the company. In May 2017, Lucas Nelson started out practicing law in Louisville, Ky., before joining Kemin. Before long, he was asked to help Bud & Mary’s apply for a license to operate.

“That’s when I was asked to come over and get it started and get it up and operational,” he said. “I did that until 2022, when I stepped into this role as the group president, overseeing everything that we’re doing.”

For Dan Ryan, son of R.W. and Mary’s youngest child Molly Nelson Ryan, Kemin was often a topic of discussion growing up.

“It’s always been present. Whenever the family gets around for vacations, Kemin always pops up,” he said. “It became a lot more prevalent when I turned 13, that’s when you start sitting in on a little bit more of the business side, so you sit in on quarterly calls, you do a little bit of business review every year as part of the family vacation, just because everyone’s there and it’s easier to talk.”

As the company has grown, the focus of those meetings has shifted, he said.

“It has certainly gotten more interesting as Kemin has grown globally,” Ryan said. “You start hearing more, not just U.S.-centric news, but you start hearing how Kemin is doing in Europe, how Kemin is doing in China. How it’s doing all over Asia, Africa, South America. So as time has gone on, it has certainly become more complex and a lot more interesting and a lot more time consuming to keep up with everything. It does certainly help to learn and know what Kemin is doing and how Kemin can impact, really, the globe.”

Ryan attended Iowa State University and worked at Corteva Agriscience, where he focused on soybean transformation and vector creation. Family members, before joining Kemin, must work for another company and get a promotion within the first two years.

While Ryan was 13 years old when he started sitting in on business calls as a member of the Nelson family, he began actively working at Kemin six years ago as a microbiologist in the food division. He stayed in that position for three years before moving to Singapore for a product manager position in Singapore. He returned to Iowa in 2025, working in a technical service position, or what he describes as a “scientist that can talk to people.”

“I basically support the sales team through their sales calls and interactions with customers by being more of the technical voice on those calls,” he said. “If there are any technical questions about products, or if they have a specific problem they need more technical advice on, that’s what I help with.”

A way in which Kemin stands out in the industry is its ability to respond to customers quickly, he said.

“We can drop everything and work on that problem as a whole team and group,” he said. “Each business unit can respond to customers extremely fast. We can get research and development through extremely fast. I would say that is extremely unique.”

Future growth

Chris Nelson said the company plans to continue to grow its business and employee base globally and in Des Moines.

“Lots of things depend on how markets develop, and I would say, a little bit on taxation, as well. The research and development tax credits are really important to us,” he said.

He expects company growth to occur in vaccines, enzyme manufacturing and encapsulating ingredients as a delivery mechanism for people and animals.

Meet the Nelson family’s second generation and current leaders

R.W. and Mary Nelson’s eldest son, Chris Nelson, studied science at Northwestern University before attending Washington State University, earning a doctorate in biochemistry and biophysics. He and his wife spent three years in Herentals, Belgium, where Kemin operated a regional headquarters that needed a research director. He returned to work at the Des Moines location in 1983. His daughter, Kimberly Nelson, has joined the company.

Libby Nelson, the second oldest of the family, attended Washington University in St. Louis before earning her law degree from Drake University. She started out working for a trust company in Milwaukee before returning to Iowa in 1981. She served the state of Iowa in the Department of Aging and the Attorney General’s office, Iowa Industrial Commissioner and worked in private practice before joining Kemin, where she is now chief legal counsel.

Janet Nelson earned a master’s degree in social work from Washington University in St. Louis, a master’s in business administration from Regis University and worked as executive director of the Cathedral Mission Society before developing an interest in business and computers. She lived in Denver for a time before returning to Des Moines and worked at Kemin for several years as a web editor and then in business intelligence and sales, developing sales and marketing strategies for products. She is now a business and career coach.

David Nelson studied at the University of South Dakota and then at Southern Illinois University and is a real estate developer in the southern Indiana-northern Kentucky region. He has served on the Kemin board of advisors and consults on real estate. His son, Lucas Nelson, started with Kemin as an attorney and is now president of Bud & Mary’s brands.

The youngest of R.W. and Mary’s children, Molly Nelson Ryan, studied business and computer science at the University of Iowa and later worked as a network administrator for the Iowa Judicial Branch. She moved to her husband’s family farm near Cresco in northeast Iowa, where she managed the farm’s finances and worked for Howard-Winneshiek school district food service. The family has since moved back to Des Moines and she worked as the food service director at Dowling High School for 18 years before retiring in 2024. She serves on the Kemin Board of Advisors and her sons are involved at Kemin. Dan Ryan works at Kemin as a technical sales manager focusing on human food ingredient products and Ben Ryan, who is finishing his doctoral work at the Massachusetts Institute of Technology will begin work at Kemin’s vaccine subsidiary in February as a researcher.

Kemin Industries: How it started

Initially Chemical Industries, Kemin was started in 1961 by R.W. and Mary Nelson in Des Moines. R.W. Nelson had been working for McKesson & Robbins, an animal feed additives and pharmaceutical distributor. He shared a new product idea with his employer, but found no interest. So he left McKesson and joined Flavor Corporation of America, and again found no support for his idea. Nelson left the company and started his own. At that time, Turkey X, a bird disease associated with Brazilian groundnut meal feed, killed 100,000 turkeys. Scientists discovered aflatoxins were to blame. A dangerous toxin, aflatoxins come from a mold in animal feed.

“He had an idea for mold inhibitors,” Chris Nelson, Kemin’s president and CEO said of his father’s business start. “He formulated some products specifically for animal feed, then silage and hay.”

R.W. Nelson went global during the first years of business. In 1964, he flew to the U.K. and set up a distributor.

“At that time, to fly to the U.K., you flew from Des Moines to Chicago, Chicago to New York, New York to Halifax [Nova Scotia, Canada], Halifax to Reykjavík [Iceland], Reykjavik to Shannon [Ireland], Shannon to London. It was a big deal to go overseas,” Chris Nelson said.

Going global early allowed Kemin leaders to build relationships in multiple countries, which helped foster shared ideas and innovations.

The Nelsons’ first manufacturing facility was a wool barn 2 miles southeast of the state capitol, owned by R.W. Nelson’s father, Bart Nelson.

The $1 billion company now manufactures more than 500 specialty ingredients for several industries on a 70-acre campus in Des Moines and 17 manufacturing facilities globally. A $30 million headquarters was built in 2017 on the same spot where the wool barn once stood. The headquarters project was part of a $125.5 million five-year commitment to grow the company. A $4.5 million expansion began in 2021 and work on a $28 million warehouse started in 2024. The facilities have advanced research facilities, pilot labs and office space.

To further that investment, Kemin recently acquired Hennessy Research Associates of Lenexa, Kan., which specializes in the research and development of vaccines for infectious diseases in animals. Hennessy Research Associates will operate in the Kemin ecosystem, specializing in manufacturing vaccines and supplying veterinary biologicals as a contractor and manufacturing service provider. With this acquisition, Kemin expands its portfolio to include contract vaccine research, development and manufacturing, and adds more than 50 team members from Hennessy.

Gigi Wood

Gigi Wood is a senior staff writer at Business Record. She covers economic development, government policy and law, agriculture, energy, and manufacturing.