Manufacturing in Iowa ‘not hitting on all cylinders’

Layoffs, plant closures causing uneasiness in sector

Kathy A. Bolten Oct 3, 2025 | 6:00 am

11 min read time

2,605 wordsBusiness Record Insider, ManufacturingEditor’s note: This is part one of a three-part series about the state of Iowa’s manufacturing sector. Part one covers Iowa’s manufacturing economy and workforce. Part two, publishing Oct. 10, will cover the strong ties between manufacturing and agriculture, and part three, publishing Oct. 17, will cover what the state and its communities need to do to attract new companies to Iowa and keep its existing manufacturers.

“Socktoberfest” began in the late 1980s as a modest tent sale on the campus of Fox River Mills, a sock and apparel manufacturer in Osage in north central Iowa.

The sale eventually became one of the area’s most anticipated annual events, attracting thousands from Iowa and surrounding states. The sale grew so large that organizers moved it to the Mitchell County Fairgrounds with volunteers from local service groups helping ensure the event ran smoothly. Fox River Mills showed its appreciation for the extra hands by sharing some of the sale’s proceeds with the local groups.

This year, the sale will likely feel more like a farewell tour than a celebration of Fox River Mills’ deep roots in Osage, where it relocated to in 1971 from Appleton, Wis.

In August, North Carolina sock manufacturer Nester Hosiery announced it had acquired a majority of Fox River Mills’ assets and planned to shutter the Osage company’s production facilities by mid-October. About 25 Fox River Mills’ employees will remain in Osage in sales, marketing, design and planning positions. Another dozen of the manufacturer’s workers will relocate to North Carolina and just over 100 will be laid off.

“It was really a surprise; we weren’t aware that the company was being sold,” Osage city administrator Brock Waters said about Fox River Mills’ closing. “It’s tough to lose that many jobs in a town our size.”

Fox River Mills’ closure isn’t an isolated occurrence.

Since January 2024, Iowa has seen manufacturing companies shut down or announce closures of 26 facilities. Thirteen plants closed in 2024, including Tyson in Perry and Smithfield Packaged Meats Corp. in Altoona. So far in 2025, announcements have been made about another 13 closures including Jeld-Wen, which closed its window-making facility in Grinnell, and Winnebago Industries, which darkened its plants in Charles City and Waverly. The closures have resulted in the loss of 3,074 jobs, a review of Iowa Worker Adjustment and Retraining Notification notices shows. (Two plants have reopened under new ownership.)

Layoff notices issued by manufacturers are also piling up. Nearly 3,900 layoff notices were issued between January 2024 and Sept. 17, 50% more than the 1,945 issued between 2019 and 2023, state data shows.

In the past 19 months, between the closures and layoffs, nearly 7,000 Iowa workers have lost their jobs.

“Manufacturing has been in a rut the past couple years, both in Iowa and nationally,” said Ben Ayers, a senior economist for Nationwide Mutual Insurance Co.

During the pandemic, consumers bought goods nearly as fast as they could be produced, Ayers said. When the pandemic subsided, consumers returned to spending money on services and activities rather than goods. The reduced demand for goods, both in the U.S. and internationally, has caused a slowdown for manufacturers, prompting the layoffs and closures.

Uncertainty about tariffs has also played a role in the pullback, Ayers said.

In August, the manufacturing sector contracted for the sixth straight month, although the contraction rate was slower than in July, according to the Institute for Supply Management’s Manufacturing Purchasing Managers’ Index. The index measures the health of the manufacturing sector through a survey. Much of the slowdown has been due to lower production levels and maintaining workers rather than hiring new ones, the report said.

“I think this is indicative of a sectoral recession within manufacturing that has occurred over the past couple years,” Ayers said. “Unfortunately, it’s more likely that it gets worse before it gets better.”

Importance of manufacturing to Iowa

Seventeen percent of Iowa’s total gross domestic product is tied to manufacturing, the third highest in the country behind Indiana (26%) and Louisiana (18%), 2024 calendar year data from the U.S. Bureau of Economic Analysis shows.

Advanced manufacturing is Iowa’s largest industry, contributing $35.1 billion annually to the state’s economy, according to the Iowa Economic Development Authority. The sector contributes more to Iowa’s economy than growing corn and soybeans and raising pigs, chickens and dairy cows.

Over 13% of Iowa’s nonfarm workers are employed in manufacturing, state data shows. The average hourly wage for manufacturing employees in August was $25.88, or nearly $54,000 annually, according to data from the Federal Reserve Bank of St. Louis.

Several new manufacturers to Iowa and some that are expanding will offer salaries that exceed the state average for manufacturing pay. Nearly 60 jobs at JBS Foods’ proposed processing plant in Perry will include salaries of about $65,000 annually. A few of the jobs created by the expansion of Robinson Inc. into Iowa will include jobs that pay over $76,000 annually.

“There are some industries that have high wages but not a lot of workers; there’s some industries with a lot of workers but not high wages,” said Michael O’Donnell, director of Iowa State University’s Center for Industrial Research and Service, or CIRAS. “Manufacturing hits both – it’s high wages and a lot of people.

“If you’re looking at what drives the middle class in Iowa, manufacturing is a massive component of that.”

But growth has been stagnant in the past decade for manufacturing, Iowa’s largest industry.

Between 2014 and 2024, the GDP of Iowa’s manufacturing sector grew by just 2.1%, from $34.37 billion to $35.1 billion, according to the federal economic analysis bureau. (The growth is chained to 2017, a technical way of adjusting for inflation.)

Other sectors saw much larger rates of growth. The finance and insurance sector, the second largest contributor to Iowa’s GDP, grew by 26% between 2014 and 2024, data from the federal agency shows. The retail trade grew by 36% and information grew by nearly 51%.

While Iowa produces myriad goods and employs thousands of people who make the products, the sector isn’t growing, said Peter Orazem, a professor of economics at Iowa State University.

“Iowa is not exactly hitting on all cylinders,” Orazem said. “Some of that is because the things that we are good at [making] have weak market demand right now.”

Manufacturing and the farm economy

Contributing to Iowa’s stagnant manufacturing sector is the downturn in the farm economy. In 2024, farmers in Iowa – and the nation – experienced a decline in net cash farm income. And while the U.S. Department of Agriculture is forecasting an increase in net cash farm income in 2025, producers of corn and soybeans are expected to see profits drop while the cattle and hog sectors are expected to see increases.

Adding to farmers’ uneasiness are rising costs for feed, fertilizer and equipment, uncertainty around trade policies and continued delays in the passage of a new farm bill by federal lawmakers.

The apprehension has caused farmers to delay making major purchases or upgrading their equipment. That, in turn, has meant lower demand for tractors and harvesters. In its most recent quarterly report, Deere & Co. said net sales were 9% lower than a year ago; net sales for production and precision agriculture were 16% lower.

The decline in sales has prompted the maker of agricultural, construction and forestry equipment to cut its workforce. Since January 2024, Deere has idled nearly 2,100 of its Iowa workers.

Before the layoffs, just over 13,000 people worked at Deere’s Iowa facilities. The manufacturer has the highest concentration of plants – five – and employees in Iowa, according to a company spokesperson.

The company has 60 plants in the U.S. and over 30,000 employees, according to its website.

“As is common in manufacturing, production schedules at each John Deere factory vary to align with seasonal farming needs,” a Deere spokesperson wrote in an email. “When fewer orders come in, each factory adjusts accordingly. Throughout this process we remain focused on providing customers the high-quality equipment they depend on, while investing to strengthen the foundations of U.S. manufacturing.”

Deere officials, during August’s earnings call, offered a glimmer of optimism that this fall’s harvest, particularly in the Midwest, could spark an increase in economic confidence among producers.

“We think we’re going to have good yields,” Joshua Jepsen, Deere’s chief financial officer and senior vice president, said during the call. Good yields “will drive better outcomes for customers, which can in turn, drive demand [including] purchase decisions post-harvest. … We’ll learn a lot over the next 60 days.”

Manufacturing workforce declines

In 1999, Iowa had 255,000 manufacturing workers, the most in the 45 years between 1990 and 2025, state workforce data shows. The number plummeted during the Great Recession, dropping to 199,900 in 2010. Employment was increasing in the sector just before the start of the pandemic and then fell when manufacturers darkened plants to help lessen the spread of the disease.

Consolidations, bankruptcies and acquisitions were contributing factors in 10 of the 26 plants that have closed in Iowa since January 2024. When Nester Hosiery bought Fox River Mills in August, it only acquired the Osage company’s assets.

“Our configuration and the size of the businesses do not support manufacturing in two different places,” Kelly Nester, CEO of Nester Hosiery, wrote in an email. “Our commitment to our investment in manufacturing in North Carolina was made clear.”

During COVID, there was an increased demand for products and manufacturers ramped plants back up and hired more workers. For a while, the top issues for companies were “people, people, people,” O’Donnell, the CIRAS director, said. Now, the top issues are people and cost,” he said. The cost to make products has grown in the past couple years, O’Donnell said. “That’s both people costs and capital costs [in terms of] high interest rates and materials costs. They’ve all continued to grow. [Manufacturers] are trying to figure out how to get those costs under control.”

Some manufacturers, like Ankeny-based Kreg Tool, have maintained a workforce of about 180 for the past two years. In 2022, the tool-manufacturing company was in a “shrinking mode” because of its high inventory, CEO Ed McGreen said.

“Demand, coming out of COVID, was declining for retail goods,” McGreen said. Consumers weren’t buying products “so for the past two to three years we’ve been managing our levels of production to meet the needs we feel like we have today.”

When vacancies occur, the company assesses whether the position is still needed, McGreen said. “If it’s a need we believe needs filling, we fill it. If not, we don’t fill it. But over the past couple of years, we have not added any brand-new positions.”

Whether Kreg Tool adds workers in the coming year will depend on consumer demand, McGreen said. In July, consumers began purchasing more of the tools the company produces for woodworkers and do-it-yourself enthusiasts.

“We don’t know if that is broad-based or whether it was just a blip,” he said. “Consumers may feel slightly more confident.”

Challenges facing manufacturers

Uncertainty about tariffs is probably the biggest challenge facing manufacturers, said Debi Durham, director of the Iowa Finance and Economic Development authorities. “Finalization of trade agreements would basically be the most beneficial for us.”

Earlier this year, President Trump enacted a tiered-tariff policy that includes a universal baseline tariff on most imports and higher, country-specific tariffs determined by trade deficits. A key objective of the tariffs is to encourage more production in the U.S. and reduce dependence on foreign supply chains.

Some agreements are in place and frameworks for others have been agreed to in principle. But agreements with countries like China and India have not yet been reached.

Durham, who with other Iowans visited India in September on a trade trip, said she has had an increase in queries from companies asking about reshoring opportunities. “When we were in India, we met with a couple of manufacturers in the pharmaceutical space and they are clearly looking for a U.S. presence.

“So, yes, we’re seeing an increase in the cost of materials but we’re also getting some good prospects.”

Interest rates have also been a challenge for manufacturers, Durham said. “If we can lower interest rates more and finalize these trade agreements, then I think Iowa is positioned to see some pretty good strong years, particularly in the manufacturing space.”

Nicole Crain, president of Iowa Association of Business and Industry, has a different view on the challenges facing Iowa’s manufacturers. “In our CEO survey, the workforce as a whole remains the No. 1 challenge including retention and retraining,” she said. “Our companies are having a tough time finding the right people, making sure that they are trained, even making sure that they are qualified to start work on a production line.”

The recent layoffs and plant closings in Iowa may provide other companies with an opportunity to hire experienced production workers, O’Donnell said.

“Whether I’m a small or large manufacturer; whether I’m looking for technical or non-technical skilled workers; whether I’m in an urban or rural area, these layoffs have created some huge opportunities for companies who are now seeing people suddenly available who have deep manufacturing skills,” he said.

That is what is occurring in Osage, Waters, the city administrator, said. The community of about 3,600 has several manufacturing companies including Osage Manufacturing, which makes aluminum windows and doors, and Valent BioSciences, which makes products that control pests and diseases, he said.

“These companies are still hiring and they’ve absorbed some of the Fox River Mills workers and some would like to hire even more,” Waters said. “So, losing jobs is not an easy thing, but we are moving forward.”

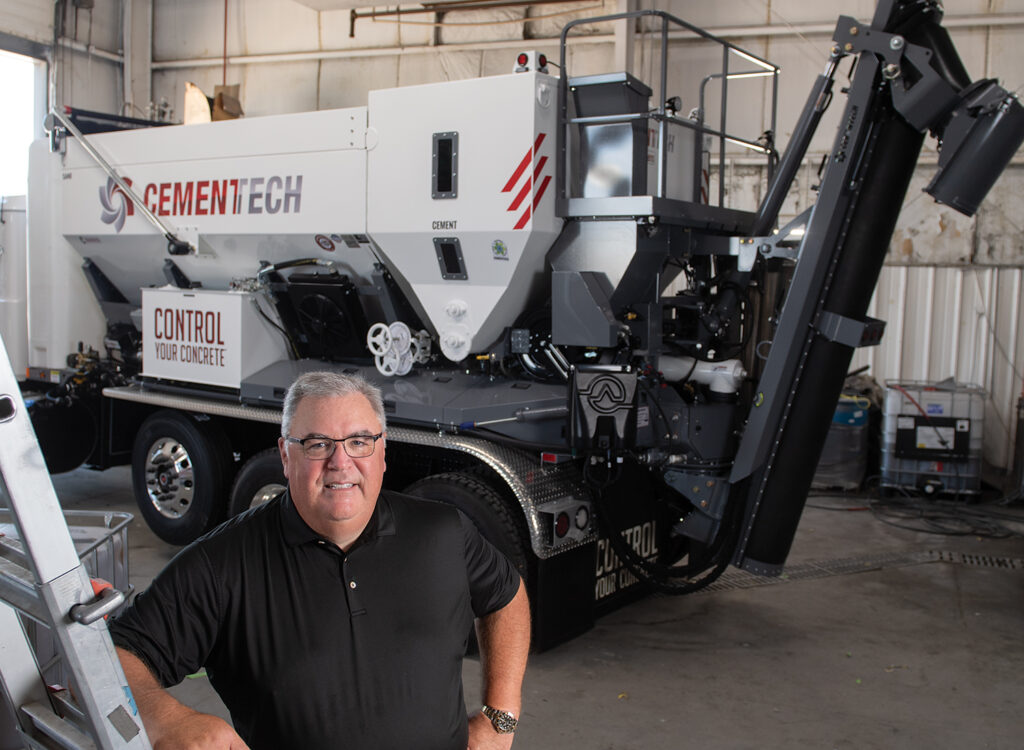

Expanding Kreg Tools’ line of products, footprint

In October, Kreg Tools will introduce cordless tools, one of which is pictured above, to its extensive line of products for woodworkers and amateur craftsmen.

The new line is the “largest product launch in the history of Kreg Tool,” said Ed McGreen, CEO of the company that is headquartered in Ankeny. “It’s a natural extension of the tools that Kreg has been making.”

The new product line is also a way to boost sales among existing customers and attract new ones. During the past couple of years, consumer spending has slowed with some becoming more selective about the products they purchase. The slowdown in spending has caused some manufacturers to lay off workers or darken their factories.

And while Kreg Tool hasn’t laid off employees in the past two years, it has been keeping a close eye on sluggish sales and making sure it didn’t overproduce its products, McGreen said.

Producing durable goods “is pretty much a supply and demand issue,” said Debi Durham, director of the Iowa Finance Authority and Iowa Economic Development Authority. “When you make something [consumers] want, they’ll buy it. But you also have to make sure you have enough markets” in which to sell the products, she said.

Kreg Tool is not only introducing a new line of tools, it is also hoping to slowly expand its footprint in the European market.

Six years ago, the company opened a sales office near Munich, Germany. It recently began assembling some tools at the facility, which also serves as a distribution point, McGreen said. About 5% of Kreg Tool’s sales are in Europe, he said.

“Obviously, we’d love to attract as many customers as we can to the Kreg brand,” McGreen said. “We are hoping this new line will help do that.”

– Kathy A. Bolten

Kathy A. Bolten

Kathy A. Bolten is a senior staff writer at Business Record. She covers real estate and development, workforce development, education, banking and finance, and housing.