Cemen Tech expects to double growth in next 5 years

The employee-owned company is doubling down on growth, betting its “batch plant on wheels” can redefine how concrete is poured in the U.S. and beyond

No industry is set in stone.

Indianola-based Cemen Tech has been shaking up – or vibrating – the cement and concrete industry with its volumetric mixer trucks.

Roads, bridges, buildings, parking lots and sidewalks are critical infrastructure often built of concrete. Second only to water, concrete is the most highly used building material. About 4.2 billion tonnes of cement is produced annually worldwide, according to the Global Cement and Concrete Association, and 88 million tons yearly in the U.S., according to the U.S. Geological Survey. With a $68 billion market value, concrete production and delivery is a major American industry.

Volumetric mixers allow concrete to be mixed and placed on the construction jobsite, which Cemen Tech leaders say is the modern alternative to waiting hours for concrete deliveries, and the mixers they manufacture allow for less waste through custom batching.

Cemen Tech is one of 10 companies globally producing volumetric mixers, a market that is expected to grow by 6.9% CAGR, or $84.4 million to $175.83 million, from now to 2033, according to market research reports.

Cemen Tech expects to increasingly cash in on that market. The company manufactures its line of mixers and related equipment in Iowa, then sells them across the nation and to companies in more than 70 countries. Connor Deering, Cemen Tech’s president and CEO, said the company’s goal is to double sales during the next five years.

“If you look at the universe of concrete being poured, 2%, maybe 2.5% of the concrete poured in the United States today is poured through a volumetric mixer,” he said. “That’s really low, which tells us that we have an enormous opportunity for growth. The biggest challenge to that, which is surprising given that the business is 57 years old, is education. It is helping people understand what it is, what a volumetric is, what it does, and the fact that it can pour fantastic concrete.”

The industry’s largest tradeshow, World of Concrete, takes place each January in Las Vegas. Cemen Tech regularly attends to showcase the mixer trucks to contractors.

“Eleven years ago, if you’d walked into World of Concrete and asked 100 people what a volumetric mixer was, half of them would have no idea what you’re talking about,” Deering said. “The other half, you’d have varying degrees [of understanding] from somebody maybe being able to point one out, but really not understanding what it is or what it does. We half jokingly talk about the fact that we’re a 57-year-old startup.”

A concrete batch plant on wheels

Many people have likely seen a traditional concrete drum truck, which uses a large drum that rotates to continuously mix ingredients until they are ready to be poured. The concrete drum truck driver travels to a batch plant to pick up sand, gravel, cement and water to produce the concrete needed on a construction jobsite. The amount of concrete needed is determined ahead of time, and the ingredients are precisely measured at the batch plant for each load. Those ingredients are then added to the drum, which rotates to keep them from hardening.

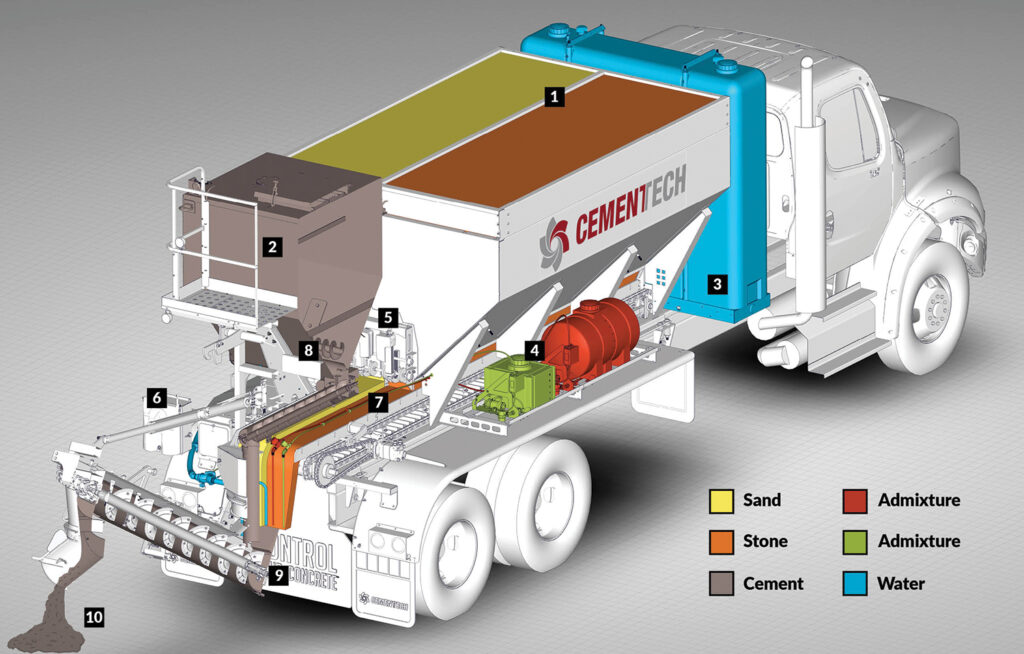

With volumetric mixers, each ingredient has its own compartment on the truck. The operator tells the mixer what concrete mix, or strength, is needed. The truck measures and mixes those ingredients, creating the correct concrete mix and volume needed, and does so on the jobsite.

“Our unit has all the ingredients to make concrete segregated on board. It has the water, the sand, the aggregate, the cement powder, admixtures, and then it mixes it fresh on site. It can do that either in a batch or you can feed ingredients into the truck, and it can pour from a continuous perspective,” Deering said. “Our most popular unit is a C60 10-yard version, and that can make concrete at a rate of a yard a minute. We’ll have customers that set all the ingredients up on site and feed the truck, or trucks, in some instances — they’ll pour 900 yards in a day through two trucks.”

One of the most significant inefficiencies on a construction jobsite is running out of concrete.

When that happens, another concrete pickup needs to be scheduled at the batch plant, and that’s assuming the plant hasn’t run out of ingredients. Meanwhile, the crew on the jobsite is often left standing around until the truck returns.

“If that’s 20 people [on the jobsite], [with a volumetric mixer on site] they’re not standing around for three hours waiting for the concrete to be able to finish it. If they wanted it at 3 o’clock that day, because they own our trucks and they control it, they get it at 3 o’clock that day,” Deering said.

Custom mixes can be created and changed on the spot, and the volumetric mixer can produce various quantities. For example, if a business or homeowner were to replace the sidewalk in front of their building, a concrete contractor would need to build the sidewalk slabs, a curb and a street panel. Each component has different strength requirements, measured in pounds per square inch, or psi.

“You might have a 3,000 psi sidewalk, a 4,000 psi curb and a 5,000 psi street panel,” Deering said. “Those would be three separate ready-mix trucks. In that particular application, the quantities would be pretty small, so it wouldn’t be all that [financially] attractive to the ready-mix guys [concrete contractors]. With our technology, it’s one truck, all the same ingredients, all the adjustments to the mix and designs to give you the ability to pour all of those things from one truck.”

Volumetric mixer trucks were once known for being ideal for small concrete pours, but they have the capability to perform large pours as well.

Sustainability

Producing cement and concrete in the U.S. is big business. It’s even bigger business in China, which consumes as much cement in two years as the United States did during the entire 20th century.

Cement and concrete manufacturing leads to 8% of the world’s carbon emissions globally, making it one of the largest global carbon polluters. Deering said there are several ways volumetric mixer trucks reduce that carbon impact.

“The ready-mix guys have a large plant that’s consuming electricity. They then have a fleet of trucks, which we do as well, but that drum on that truck has to continuously turn. You’ll see pictures of jobsites where you’ll have 10 to 15 of these drum trucks stacked up, and every single one of those trucks is running because it has to run to turn that mixer,” he said. “With ours, because you have all the ingredients segregated on board, and you don’t actually mix it until you need it, if we show up on a jobsite and the contractor isn’t ready to pour concrete, we turn the truck off. From an environmental perspective, volumetric concrete mixing is far more environmentally friendly than the traditional batch plant and drum truck method.”

Some customers have shown interest in electric volumetric trucks, he added.

“We’re actually the first manufacturer who’s had a volumetric mixer mounted on an electric chassis, and that happened with our dealer in the Netherlands. We’ve got a customer in California who would love to get that done,” he said.

Truck manufacturers, at the moment, tend to not be actively designing electric, heavy-duty vocational trucks that could be used for these applications.

“The city of New York runs a fleet of electric garbage trucks and there’s regenerative braking [that capture energy during stops], or there are delivery trucks that are going out, making one or two deliveries and going back, and that’s easy,” he said. “But we use a [Power Take-Off] to power our unit off of the truck engine. It’s consuming energy going to the site, you’re consuming energy delivering the concrete. It becomes a little bit more challenging. Not that it can’t be done, but it just becomes a little bit more challenging in terms of how do you do that and still be able to drive the truck down the road and have battery left?”

Differentiators

An emphasis on customer service and diversification are a few differentiators between Cemen Tech and its competitors, Deering said.

About a decade ago, Cemen Tech started building out a dealer network to better serve customers, and developed its Accu-Pour technology to create more specific mixes and pours. The company also runs a 24-hour parts program that delivers truck or mixer parts to customers quickly and will take a truck back if the customer isn’t satisfied.

Cemen Tech Connect is the company’s technical support service, which combines video calls with other technologies to assist customers in the field. On the video call, users can circle objects on the screen for better communication. Cemen Tech also has six regional tech support managers across the country to help customers with parts, maintenance and repairs.

“The customer can call in to us or we can initiate an outbound call, and now we can see exactly what they’re talking about,” Deering said. “We can hear, if there are noises involved, we can hear those things, so we get to a common understanding much, much faster, and we’re able to solve those issues much, much faster. We’re the only ones in the industry that have that type of technology.”

Cemen Tech has also diversified its business beyond mixers. It offers Cemen Tech Momentum, the company’s in-house marketing services for customers, including website design, SEO services and video production.

“Let’s say they’re a utility contractor. They’re great at putting pipe in the ground. They’re maybe not so great at marketing their business. We can do that for them. It’s a demand-generation strategy where we help their business grow,” he said.

Cemen Tech Capital is the company’s in-house financing arm with a $50 million portfolio of loans for potential customers.

Manufacturing in Iowa

The company, which uses an Employee Stock Ownership Plan, employs 150 people who work in sales, administration and manufacturing.

“We’re different on how we approach the product side and the employment side. We return millions of dollars every year to people in this community that have built wealth through sweat equity here at Cemen Tech. We’re one of the oldest ESOPs in the community and we like to champion that wherever we go,” said Josh Maurer, Cemen Tech’s chief financial officer.

Deering said the company plans on remaining in Iowa.

“I’ve never given a whole lot of thought to, could we do it cheaper in China? Sure, we could. But it comes with a whole host of other problems and issues. Does that mean that at some point in the future, we won’t have another manufacturing site at some point around the globe? I wouldn’t say that, but today, our strategy is to deliver you an American product. North America is our biggest market. We’re going to continue to manufacture right here, not only in the U.S., but in Iowa,” he said.

Deering said the company is always looking for ways to upgrade the Indianola factory with automation technology and more efficient equipment. He said one of the company’s greatest challenges is finding people who want to work in the trades and are willing to learn how to do the job.

Iowa’s biggest challenge, he said, is affordable housing.

“It’s a complicated issue with many tentacles, but we’ve got to do more to solve that issue, because there are a ton of great manufacturing businesses in Iowa that will all be in the exact same boat, and that is going to have major implications from a growth perspective,” he said.

A few years ago, the company started Cemen Tech University to teach workers the skills needed to work there.

“Our intent with Cemen Tech University was to hire an unqualified person with a great attitude and train them to be qualified so that they had a career,” he said. “Think welder, for instance, think somebody who has a great attitude and wants more out of life and is working at McDonald’s, and not that that’s bad, but we hire that individual, we spend time and money giving them the skill to be able to weld, and now they have a career, and that’s different.”

One of Deering’s ideas to ease the workforce shortage is to set up trade schools south of the U.S.-Mexico border, where future U.S. immigrants can learn trades skills while working toward visa or citizenship.

“Think of it almost like a college campus. These people would have facilities where they would do training. You would have housing where they could bring their family,” he said. “Along with being trained in a skill like welding. They also go to citizenship classes, and they learn what it means and what it takes to be an American citizen. And then companies have the ability to come in and recruit from there. Now, instead of people randomly crossing the border, coming in and looking for any opportunity, you’ve got someone with skill that the manufacturing industry and others clearly need.”

Somehow, the U.S. needs to find more workers, he said.

“There’s just not enough people, period,” Deering said. “Immigration has to be part of the solution to that problem. How do we do that and create a better situation for everybody, for the immigrants who are coming across the border, for their families and for the companies who want and are in need of those folks from a workforce perspective?”

Gigi Wood

Gigi Wood is a senior staff writer at Business Record. She covers economic development, government policy and law, agriculture, energy, and manufacturing.