Public Companies: Flexsteel Industries Inc.

PERRY BEEMAN Jan 15, 2016 | 12:00 pm

5 min read time

1,103 wordsBusiness Record Insider, Lift IOWA, ManufacturingHeadquarters: Dubuque

Website: www.flexsteel.com

Ticker symbol: FLXS

Employees: 1,360

Flexsteel Industries Inc. is making a bigger play in the health care industry, developing specialized chairs for patients who have Alzheimer’s disease or who are receiving chemotherapy.

It’s another example of how the company has adapted to many changes in the world of recreational vehicles, boats, health care facilities, homes and hotel lobbies, yet has based much of its success on a blue steel spring that hasn’t changed much since its introduction in the early 1900s.

The health market wasn’t an emphasis at Flexsteel when Karel Czanderna took over as CEO in 2012. It is now.

“We make chairs for acute care and for rooms where patients are getting chemotherapy,” she said. Some models at nursing homes have wooden arms that are easy to clean.

Another chair is designed for patients with Alzheimer’s disease, some of whom like to rock. “You can rock the back of a chair a million times and it won’t break,” Czanderna said.

In the next five years, Czanderna will focus on expanding the company’s work in its various markets, from boat furnishings to retirement home chairs, from serving traditional stores to working with those who sell through the Internet.

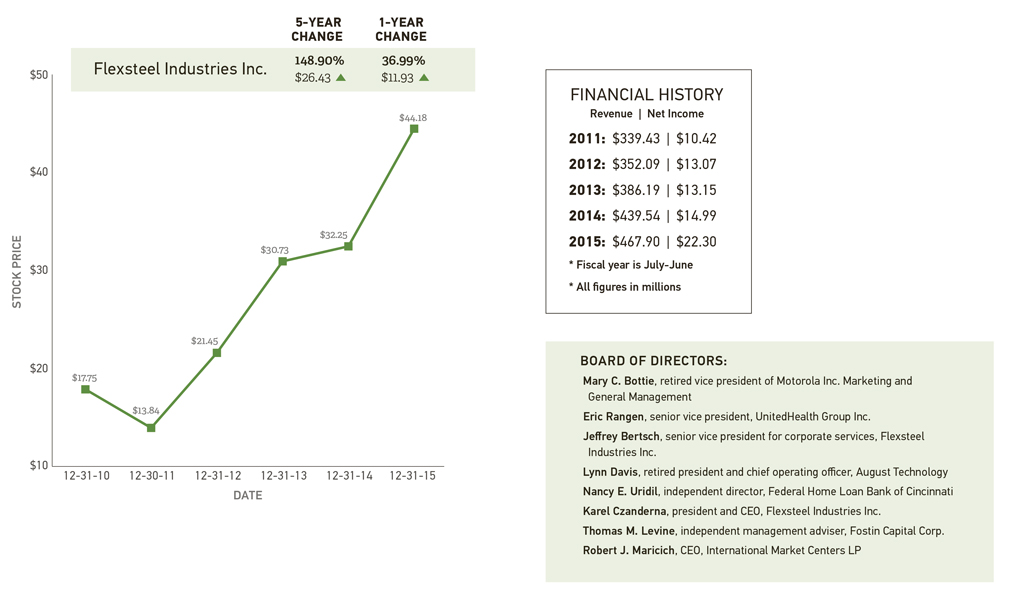

Flexsteel is a half-billion-dollar company and the country’s seventh-largest furniture manufacturer. Its net sales grew to $467 million in the year that ended June 30, up from $438 million in fiscal 2014. That figure was $339 million in fiscal 2011.

Profits rose to $22.3 million in 2015, up from approximately $15 million in 2014 and 114 percent higher than in 2011. Dividends were up 155 percent in four years, to $5.1 million in 2015.

Flexsteel sells in 50 countries and through 1,200 retailers. Among its clients: Amazon.com Inc., Home Depot Inc., Sears Holdings Corp. and J.C. Penney Co. Inc.

“We work with the large furniture stores through the small, local, independent stores,” Czanderna said. “We serve the contract market, providing furnishings for hotels, lobbies and lounges of buildings.”

Furniture for individual homes remains 82 percent of the business. The products for boats, RVs and the like and contract work with hotels and senior living and health facilities make up much of the rest.

Flexsteel now operates out of its first independent headquarters at the Port of Dubuque, where Czanderna enjoys gazing at the Mississippi River while she envisions the future for one of Iowa’s stalwart businesses. The $12 million headquarters building opened in August 2012, ending the offices’ run at the 107-year-old manufacturing site in Dubuque.

There the company continues to serve faithful customers and to recruit new ones, making upholstered seats and benches for RVs, boardrooms, hotel lobbies, hospitals, boats and homes.

“Every audience we serve is moving in the right direction,” Czanderna said. “We will continue to grow profitably.”

The company traces its roots to the formation of Rolph & Ball Furniture Co. in Minneapolis in 1893. It moved to Dubuque in 1936.

In the highly competitive world of furniture, Flexsteel is widely known for the blue steel spring in its seats, a heavy-duty but comfortable bit of technology that originated in the early 1900s and hasn’t changed much.

“They don’t break,” Czanderna said. “We are very proud of them, and in our technology. They make it very comfortable.”

Czanderna said the company has to adapt to changes. It once was big on van conversions, something auto dealers handle now. The RV industry has been up and down, but the company continues to support it.

“The RV industry had a tough time in the recession,” Czanderna said. “It dropped like a rock. Now it is recovering and almost back to where it was. The hospitality industry was struggling, but new construction is starting again. Over the next five years, we’ll continue to grow the whole portfolio.”

The company manufactures products in Dubuque and in Georgia, Mississippi, Arkansas, California and Juarez, Mexico.

The company has adapted by manufacturing in Asia, too, especially in the leather furniture market. “We sell a lot of leather furniture,” Czanderna said. “Some of it is made in the United States, but most of it comes from Asia. There are so many regulatory requirements here that it makes it almost impossible for a tannery to exist and be cost competitive.”

Czanderna knows that recessions come along every seven years on average. Obviously, Flexsteel has weathered them.

“I am seeing seeing signs of growth, but we are very conservative. We are thoughtful where we invest,” she said.

Logistics is a growing area of focus. Companies are ordering very specific items — like chairs with a certain color scheme associated with a particular hotel — and they don’t want them delivered long before the hotel opens, Czanderna said.

“Another big part of the business will be handling logistics. We ship the perfect order. It’s on time, at the right time, at the right value. I didn’t say cheap,” she said.

“When a hotel is opening, the furniture has to be there,” she said. “RV manufacturers don’t want the seats early. They want them within a day or two before that model will be made.”

Most of the company’s business is with repeat customers, though the roster of clients is growing. “If they are making money, and we are, life is good,” Czanderna said.

One challenge in the next five years is a familiar one in Iowa: workforce, or the lack of it. Flexsteel needs welders and engineers, and they can be hard to find in a state with low unemployment.

“Right now in the state of Iowa, it has become substantially more difficult to hire people,” Czanderna said. “We are having trouble hiring some types of skills. Finding people for the factory has become much more challenging, and we pay competitive rates.”

The company has tried to address the problem, though. For example, it worked with North Iowa Area Community College to help train workers in sewing.

Overall, Czanderna sees a future of adjustments to meet the needs of customers, and of making sure the company’s physical plant keeps up with the times.

“I am very positive about Flexsteel,” she said. “I joined a company that had been here 122 years and profitable all but one year. We’ve been public since 1969. We have a lot of opportunities now, in terms of modernizing our infrastructure.”

Don’t expect huge changes in the blue steel spring, though.

Flexsteel expands: Karel Czanderna, president and CEO

Age: 59

Education: Bachelor’s degree in physics and humanities, Clarkson University; master’s and doctorate in materials science and engineering, Cornell University; executive education program, Harvard University.

Hometown: Potsdam, N.Y.

Family: Husband, Dan Shirkey