Lycra athletic wear to be made with Iowa corn as Cargill opens renewable material facility

Gigi Wood Jul 23, 2025 | 1:58 pm

4 min read time

1,010 wordsAg and Environment, Agriculture & Bioscience, All Latest News, Innovation and Entrepreneurship

As one CEO put it, when it comes to fossil fuels, there are only so many dead dinosaurs in the ground.

Gary Smith, leader of the multibillion-dollar spandex maker Lycra, made the comment when he was in Eddyville on Tuesday, as part of a new collaboration between Lycra and Cargill.

Cargill uses crops such as corn and soybeans to produce oils, sweeteners and proteins. The company has several mills and facilities across Iowa, including a corn wet mill ethanol plant in Fort Dodge, a soybean-processing plant in Cedar Rapids, an egg facility in Mason City and a corn-processing plant in Eddyville.

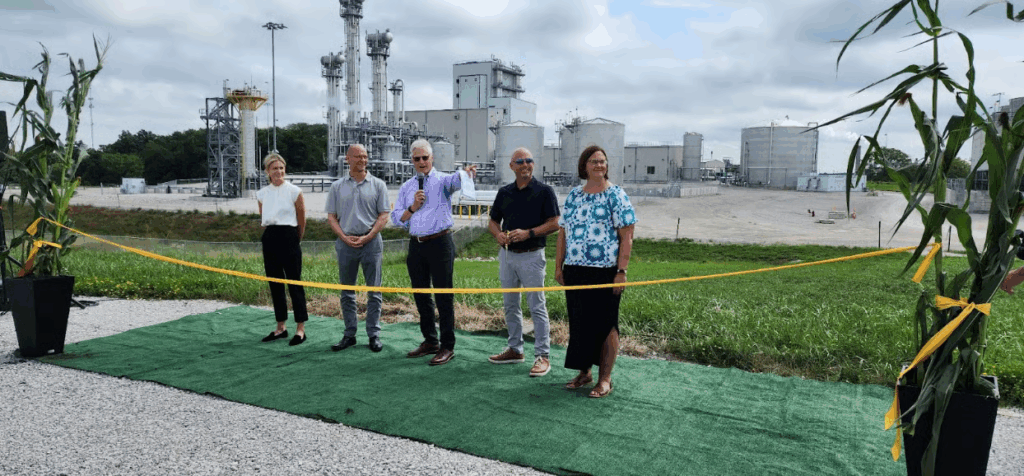

The 2,000-acre Eddyville plant produces high fructose corn sweeteners, dextrose and other food ingredients. On Tuesday, Cargill leaders cut the ribbon on the company’s newest facility, which houses Qore, a joint venture with chemical company HELM.

Qore produces bio-derived 1,4-butanediol, a chemical made from renewable biomass sources, such as Iowa-based dent corn instead of fossil fuels. This chemical is Qore’s main product, called Qira, which can be used in fashion and footwear, beauty and personal care products, automotive parts and electronics and packaging. By using Qira, companies like BASF and Lycra hope to reduce their carbon footprint.

Lycra plans to incorporate Qira into its clothing fiber and estimates doing so will reduce its carbon footprint by up to 44%. In a panel discussion about the possibilities of Qira at Tuesday’s event, Smith talked about resource acquisition in the acquisition of goods for product production.

“We’ve done wonderful things in extending fracking, horizontal drilling, shale oil, but there’s only so many dead dinosaurs in the ground, right? At some point it will run out,” he said. “We live in an unstable world and people get a little upset over resource acquisition, so the ability to have no compromise in the end products, the things we’ve all come to enjoy and have made our humanity better, but have it from a renewable source that you can grow locally, is huge to me. It’s more than a sustainability story that you can communicate to a consumer. It’s about a future where you don’t have to compromise on the standard of living that we’ve all come to know. The ability to actually have renewable inputs that replace petrochemicals is huge. I hope this is just the first step in what I hope is many of these facilities in Iowa and around the world.”

The facility is set to produce 66,000 metric tons of Qira annually, using corn grown primarily within 100 miles of the Eddyville campus. Producing that much Qira will require 30,000 bushels of corn per day, greatly increasing demand for corn in the area.

“When I first heard about this, I heard about it at an Iowa Corn board meeting and I was excited about it because that’s creating demand for our corn in our area,” said Steve Kuiper, a local farmer and member of the Iowa Corn Growers Association. “I’ve been watching the plant going up, and I’m kind of an impatient person. It’s like, ‘Come on guys, get that plant done. We need to start grinding corn.’ For our local area, it has significant economic impact.”

Cargill officials said that while the investment in the facility is considerable, it’s nothing compared to the billions of dollars the company has invested in research and development over the years to create more innovative products.

“While we’re proud of the technical sophistication of the facility behind us, we’re even more proud of what it represents,” said Jon Veldhouse, CEO of Qore. “It proves that scalable solutions can come from the groundwork, that innovation can start with corn, that the products we use every day in fashion, footwear, personal care, electronics, automotive, they can be more responsible and serve a louder purpose. Qira is no longer a concept. It’s real. It’s running through the pipes of that facility right now and soon, through global supply chains and into the hands of consumers who are ready for more.”

The state provided $4 million in investment tax credits and $2 million in tax refunds to incentivize the new project. Debi Durham, director of the Iowa Economic Development Authority and Iowa Finance Authority, said the Qore project became a reality partly because of the state’s favorable business conditions.

“In Iowa, we have worked hard, led by our governor and legislators, to create a favorable business environment, one that encourages fresh thinking, nurtures innovation and feeds growth,” she said. “Iowa’s growth in bioscience and ag tech venture deals outpaces the nation’s average by 150%.”

Colleen May, president of Cargill Bioindustrial Group, said the inspiration for Qore came from customer feedback.

“It started from a customer perspective that we had seen time and time again on the food side of our business, where consumers are making choices, where they want clean labels, they want less additives, they want to know where their food is coming from, and ideally having it be sustainably sourced,” she said. “At Cargill, we’re very large in basic manufacturing and advanced manufacturing in global supply chains, and we knew that there were technologies out there that would take those lessons of a more sustainable future that we saw in food into more industrial applications.”

Bruce Leslie, vice president of Cargill and chair of the board of Qore, helped cut the ribbon at Tuesday’s event. He noted that the new venture is at a fragile stage and needs end-user customer support.

“All of you as consumers, when you start to see the Qira tag show up, please buy it,” Leslie said.

Gigi Wood

Gigi Wood is a senior staff writer at Business Record. She covers economic development, government policy and law, agriculture, energy, and manufacturing.